اطلب اقتباس

ball mill grinding aluminum

Processing Aluminum Powder from the Ball Mill Down to 500 Mesh

标记:Ball Mill Aluminum PowderAluminum Powder 400 Mesh500 Mesh Aluminum Powder

alumina ball mill - planetary ball milllaboratory ball milllab ...

2024/7/31 The Aluminum Ball Mill: A Mechanistic Analysis The marriage of aluminum and ball milling technology gives rise to a unique and versatile tool for material ... Grinding

获取价格

Ultrafine Grinding with Laboratory Ball Mills

In the planetary ball mill, every grinding jar represents a “planet”. This planet is located on a circular platform, the so-called sun wheel. When the sun wheel turns, ... Colloidal grinding of

获取价格

Alumina Balls Cylinders - FOX Industries

Versatile Applications: Whether for ceramics, mining, or pharmaceuticals, FOX Alumina Oxide Balls and Cylinders are your versatile solution. They excel in various applications, from fine grinding to rough polishing, adapting

获取价格

Making Air Float Aluminum Powder With a Ball Mill - YouTube

标记:Ball Mill Aluminum PowderAluminum FLASH POWDERDiy Aluminium Foil

Ball Mill Success: A Step-by-Step Guide to Choosing

2024/8/8 Step-by-Step Selection Guide. Choosing the right grinding media for ball milling involves a strategic assessment to align with operational goals, material characteristics, and cost constraints. Here’s a step-by-step guide to

获取价格

Producing Metal Powder from Machining Chips Using

2023/6/27 A key component of the grinding process in a ball mill is the ball size distribution (BSD), which controls the grinding efficiency, product size distribution, and media wear rate. ... explored the possibility of recycling

获取价格

Maximizing Efficiency in Alumina Production with Ball Mill

Precision grinding lies at the heart of efficient alumina production. Ball mill technology optimizes energy usage and fuels sustainable growth in the aluminum industry. Ball mills have

获取价格

Production and characterization of aluminum powder derived

2020/1/15 The grinding was performed in a hermetic ball mill US Stoneware East Palestine, OH 44413, using zirconia cylindrical ball media, and a rotational speed of 55 rpm.

获取价格

AC3939 Alumina Wet Grinding Ball - precise ceramic

Alumina Wet Grinding Ball is a type of aluminum oxide ceramic product. ACM provides alumina ceramic products with high purity, tight dimensional tolerance, and competitive prices. ... Alumina grinding balls for ball mills (Al2O3) have

获取价格

Largest selection of grinding media Glen Mills, Inc.

Grinding bead life. As grinding beads wear they need to be replaced. The longer a grinding bead lasts the cheaper it may be in the long run because of the costs associated with downtime, new beads, disposal and labor. Mill wear. Low

获取价格

Efficient preparation and characterization of graphene based on ball ...

2022/12/1 The ball mill uses the kinetic energy and shear energy generated by the high-speed impact of the grinding ball to break the aluminum and thus open the fresh surface to adsorb graphite, which is more beneficial to the graphite stripping effect in the ball milling process. ... For improved grinding effect, the ball mill filling rate is typically ...

获取价格

Author: Subject: Ball Mill questions - Sciencemadness

2012/12/11 -What grinding media is recommended for grinding aluminum foil, and where can one obtain this media (preferably some sort of OTC)?-What is the best size for the media?-Can the ball mill (In this case, a Lortone 3A rock tumbler with rubber barrel and such) be run in the outside (it's winter now! ) to cool off the aluminum?

获取价格

Alumina Balls Cylinders - FOX Industries

UNLOCK PEAK PERFORMANCE WITH FOX ALUMINA BALLS AND CYLINDERS. When steel isn’t an option for your ball mills, FOX Alumina Balls and Cylinders offer the ideal solution. Superior to porcelain, flint pebbles, or natural stones, FOX Alumina Grinding Media is engineered to ensure optimal performance. FOX Grinding Media features unique microstructures that

获取价格

Horizontal ball mill for aluminum ash processing - Google Patents

The utility model relates to an aluminium ash processing equipment technical field, concretely relates to a horizontal ball mill for aluminium ash processing, including support and ball-milling storehouse, the ball-milling storehouse adopts the belt to drive stable the rotation, divides to carry out the preceding storehouse of corase grind and the back storehouse of fine grinding in the ...

获取价格

TECHNICAL DATA SHEET Alumina Grinding Media

GNPGraystar’s Alumin Grinding Media is used in wet grinding (batch and continuous ball mills), ceramic glaze grinding, and in dry grinding of resins, ceramic raw materials, and other mineral products. info@GNPGraystar Northern Office 37 John Glenn Dr. Amherst, NY 14228 716.759.6600 Southern Office 9 Simmonsville Rd. Bluffton, SC 29910

获取价格

Producing Metal Powder from Machining Chips Using Ball Milling

2023/6/27 A key component of the grinding process in a ball mill is the ball size distribution (BSD), which controls the grinding efficiency, product size distribution, and media wear rate. ... explored the possibility of recycling aluminum scarps into gritty powder using ball milling for metal injection molding (MIM) applications. The authors conducted ...

获取价格

Ball Mill Application and Design - Paul O. Abbe

Ball mills cab be used equally well for wet or dry grinding. In the case of wet grinding the particles are also dispersed in the liquid medium. For temperature sensitive products, ball mills can be fully jacketed to maintain temperatures of the product. Ball mills scale up well and in fact improve in performed with increasing size.

获取价格

Ball Mill Grinding Media Options Ceramic Balls for Ball Mill

Glass ball mills are ideal for grinding of pigments in mills vertically and also horizontally. Glass ball mills are particularly suited for applications in mills because of their specific mass which can process low and medium viscosity mill bases. The glass beads, that is, the glass ball meals are thermally and chemically treated to maintain ...

获取价格

Getting a mirror finish in aluminum surfacing - Practical Machinist

2007/2/20 Maybe a shot of WD-40? I've tried playing a lot with feed/speed... the best I got was 30,000 RPM, about .005 depth of cut, .005 step over and something like .0005 chip load per tooth on a 1/4 ball end mill. The PCD end mill didn't really produce a better result than a Helical tool 2fl ball end mill which surprised me.

获取价格

Aluminum dross ball mill and screening machine

Belt ball mills can effectively grind aluminum ash and improve its processing efficiency and purity. Secondly, the belt ball mill has a unique structure and working principle. It uses a horizontal cylindrical rotating device, which is driven by the outer gear to make the material hit and grind by the steel balls in the cylinder, thus achieving ...

获取价格

Producing Metal Powder from Machining Chips Using Ball Milling

2023/6/27 A key component of the grinding process in a ball mill is the ball size distribution (BSD), which controls the grinding efficiency, product size distribution, and media wear rate. ... explored the possibility of recycling aluminum scarps into gritty powder using ball milling for metal injection molding (MIM) applications. The authors conducted ...

获取价格

Grinding Balls Fritsch Vibratory Micro Mill - Gilson Co.

Impact energy of the grinding ball is freely adjustable on the mill; Range of grinding ball materials available ... Mortars are available in five different materials and are rimmed in an aluminum shell. Material: FTA-10, FTA-11: Agate. FTA-12: Sintered Corundum. FTA-13: Zirconium Oxide. FTA-14: Hardened Stainless Steel. FTA-15: Hardmetal ...

获取价格

Fabrication of aluminum flake powder from foil scrap by a wet ball

2001/10/1 Fabrication of aluminum flake powder by the wet ball milling of aluminum foil scraps and the effect of related factors were studied. As foil thickness decreases from 60 to 6.5 μm, mean size of powder milled for 30 h decreases from 107 to 17 μm. It is impossible to mill the foil without oleic acid to fabricate the flake powder.

获取价格

Aluminum dross ball mill and screening machine

Belt ball mills can effectively grind aluminum ash and improve its processing efficiency and purity. Secondly, the belt ball mill has a unique structure and working principle. It uses a horizontal cylindrical rotating device, which is driven by the outer gear to make the material hit and grind by the steel balls in the cylinder, thus achieving ...

获取价格

Producing Metal Powder from Machining Chips Using Ball Milling

2023/6/27 A key component of the grinding process in a ball mill is the ball size distribution (BSD), which controls the grinding efficiency, product size distribution, and media wear rate. ... explored the possibility of recycling aluminum scarps into gritty powder using ball milling for metal injection molding (MIM) applications. The authors conducted ...

获取价格

Grinding Balls Fritsch Vibratory Micro Mill - Gilson Co.

Impact energy of the grinding ball is freely adjustable on the mill; Range of grinding ball materials available ... Mortars are available in five different materials and are rimmed in an aluminum shell. Material: FTA-10, FTA-11: Agate. FTA

获取价格

Fabrication of aluminum flake powder from foil scrap by a wet ball

2001/10/1 Fabrication of aluminum flake powder by the wet ball milling of aluminum foil scraps and the effect of related factors were studied. As foil thickness decreases from 60 to 6.5 μm, mean size of powder milled for 30 h decreases from 107 to 17 μm. It is impossible to mill the foil without oleic acid to fabricate the flake powder.

获取价格

China Ball Mill Manufacturers Suppliers Factory - Customized Ball Mill ...

Aluminum Dross Ball Mill. Production Capacity:0.65-615t/h Discharge Size:0.074-0.89mm Ball Loading Weight:1.5-338t ... However, with the use of a ball mill, grinding can be accomplished in about a half-hour. This allows for more material to be processed in less time.

获取价格

Ultrafine Grinding with Laboratory Ball Mills

In the planetary ball mill, every grinding jar represents a “planet”. This planet is located on a circular platform, the so-called sun wheel. When the sun wheel turns, ... Colloidal grinding of aluminum oxide in the PM 100 Fig. 5: Grinding of alumina in water with 1 mm grinding balls (left) after 1 hour (blue) and after 4 hours (green) ...

获取价格

Ball Mills – fritsch

Ball Mills are the most effective laboratory mills for rapid batchwise comminution of medium-hard, soft, brittle, fibrous, temperature-sensitive and moist samples down to the finest particle size. The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding ...

获取价格

Ball Mill-Grinding Equipment-Hongji Mine Machinery

Ball mills are widely used in ferrous and non-ferrous metal mines, non-metallic mines, cement, refractory materials, chemical industry, electric power, aluminum industry, building materials, and grind. Home About Us ... The ball mill can be used for dry or wet grinding, can handle raw materials of various hardnesses, and has the characteristics ...

获取价格

Cold aluminium dross ball mill and sieving machine

The aluminum dross ball mill and sieving machine play a crucial role in dross recycling, significantly impacting the efficiency, sustainability, and profitability of the process. Here’s a breakdown of their importance: ... Improved separation: Grinding the dross in the ball mill liberates trapped aluminum from non-metallic impurities ...

获取价格

Versatile Planetary Ball Mill Upto 4 Grinding Stations

Planetary Ball Mill BM 1400+can not only perform mixing and grinding, but also meet the requirements of colloid grinding. In addition, its giant energy input can meet the technical requirements of preparing alloy with mechanical methods. ... Tungsten Carbide Sintered Aluminum Oxide) The grinding jars are marked with capacity and materials are ...

获取价格

Effect of Ball Milling Time on the Microstructure and Properties of ...

2023/8/23 The ball mill used was a XQXM-2 planetary ball mill. A consistent ratio of 10:1 for the ball material was upheld during the ball milling process, and a grinding speed of 200 r/min was sustained. The grinding periods were differentiated, with durations set at 2 h, 4 h, 6 h, 8 h, 10 h, and 12 h, respectively.

获取价格

Aluminum Hydroxide Ultrafine Grinding Machine Ball Mill with

The ball mill adopts special design and suitable proportion of grinding medium to achieve ideal grinding fineness; The slab-type grinding tail discharges, the discharging is smooth, and the cylinder does not need to be cooled;

获取价格

Ball Grinders - McMaster-Carr

Choose from our selection of ball grinders, including carbide ball end mills, high-speed steel ball end mills, and more. In stock and ready to ship. BROWSE CATALOG. Abrading Polishing; Building Grounds; Electrical Lighting; ... High-Speed

获取价格

Effect of Ball Milling Time on the Microstructure and Properties of ...

2023/8/23 The ball mill used was a XQXM-2 planetary ball mill. A consistent ratio of 10:1 for the ball material was upheld during the ball milling process, and a grinding speed of 200 r/min was sustained. The grinding periods were differentiated, with durations set at 2 h, 4 h, 6 h, 8 h, 10 h, and 12 h, respectively.

获取价格- موردي المعادن والمصدرين في جنوب أفريقيا

- محمصة بن مطحنة بن للبيع

- كسارة الحجر جزء للبيع

- طحين الشباتي من المطاحن

- جص تعدين الذهب

- حدود العتامة لكسارات الصخور

- المطاحن في فيصل آباد

- مدرسة المعدات الثقيلة بالاسماعيلية مستقبلها فى الكليات والمعاهد

- تكلفة آلة صنع الرمل المستعملة

- الصخور المحمولة كسارة للإيجار

- خزنده موبایل ویژگی های سنگ شکن

- سحقت المورد روك klang

- مواصفات الصوامع المستخدمة لتخزين الفحم

- سحق قوة من الحجر في هندوراس الجمهورية

- مصغرة آلة طحن الاسطوانة الولايات المتحدة الأمريكية

- فیلم تولید تجهیزات کشاورزی

- تجهيزات طحن الجرانيت

- كسارة الفحم شاشة الصانع الهندي

- سعر مصنع محجر الحجر في كينيا

- مطحنة أو الطارد البلاستيك

- صخرة محجر الكسارات روتشستر في نيويورك تتوقع

- مبدأ تهتز شاشة Pdf

- الكسارة ة الإجمالية للبيع

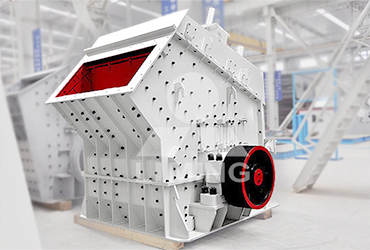

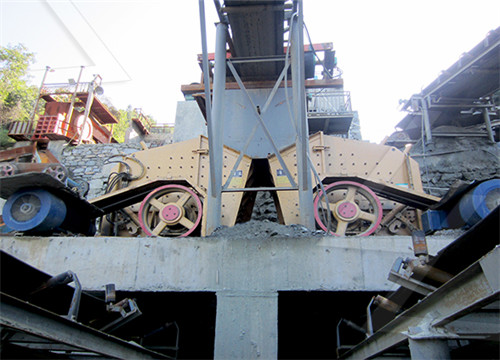

- كسارة الفك كسارة الفك كسارة الصدم

- النباتات التعويم في الصين

- مصنع آلات الكلنكر ومصنع الأسمنت

اقرأ أكثر

اقرأ أكثر