اطلب اقتباس

jaw crusher performance analysis

Dynamics Analysis of Compound Pendulum Jaw Crusher with

Abstract: Previous dynamic studies of the complex pendulum jaw crusher neglected the bearing clearance between the eccentric shaft and the moving jaw, which is crucial for analyzing the effect of bearing clearance on the dynamic performance of the crusher. By employing the Lagrange

获取价格

Capacities and performance characteristics of jaw crushers

tory data of Hersam. In addition, the performance of indus- trial jaw crushers was analyzed using the proposed equation in combination with that of Bond (1961) for calculating the energy

获取价格

Study of Kinematic and Dynamic Analysis of Jaw Crusher - A

The reduction ratio of jaw crusher is 3:1 to 5:1. This paper focuses on review of a work done by researchers in the field of kinematic and dynamic analysis of jaw crusher attachments.

获取价格

Dynamics Analysis and Chaos Identification of Compound

Capacities and performance characteristics of jaw crushers

1994/5/1 By using the data of E.A. Hersam and F.C. Bond’s equation for energy consumption in comminution, a method was developed to analyze the performance of

获取价格

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

2017/6/30 Moreover, the wear of the jaw liner profile lowers the crusher performance by affecting the shape and the overall size of the crushed particles [12, 13]. Warping and wear of

获取价格

(PDF) Optimum design and analysis of (the) swinging

2010/4/30 A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields. The performance of jaw crusher is mainly determined by the kinematic features ...

获取价格

Improvement of Jaw Crusher Design by DEM FEA Approach

Fig.3 shows the configuration of the jaw crusher and geometrical and operation parameters are given in Table 1. Jaw crusher mainly, consist of moving jaw, eccentric shaft, flywheel and

获取价格

Design and Analysis of Swing Jaw Plates of Jaw Crusher

Keywords: Finite Element Analysis; Swing Jaw Plates; Jaw Crusher; I. INTRODUCTION Jaw crusher is one of the main types of primary crushers in a mine or ore processing plant. The

获取价格

Jaw crusher kinematics simulation and analysis - IJRES

Jaw crusher kinematics simulation and analysis. International Journal of Research in Engineering and Science (IJRES) ISSN (Online): 2320-9364, ISSN (Print): 2320-9356 ijres

获取价格

Capacities and performance characteristics of jaw crushers

tory data of Hersam. In addition, the performance of indus- trial jaw crushers was analyzed using the proposed equation in combination with that of Bond (1961) for calculating the energy requirement in size reduction. The equation for capacity The volumeof material (V) that passes through the crusher bottom opening per stroke is given by:

获取价格

Optimization of Jaw Crusher - Bonfring

improve the performance of a jaw crusher, is mainly determined by the kinematic features of the liner to optimize the frame, design the chamber and recognizing the crushing ... stiffeners, and three stiffeners to the 140mm swinging jaw plate. During this analysis width of the toggle plate is considered as 800mm and toggle is located at 100mm ...

获取价格

DEM Simulation of Laboratory-Scale Jaw Crushing

2020/8/14 Some aspects of the crusher materials and a failure analysis of a jaw crusher have been investigated by Olawale and Ibitoye . ... H.E.; English, J.E. Theoretical analysis of the performance of jaw crushers. IMM Trans.

获取价格

Failure analysis of jaw crusher and its components using ANOVA

2015/7/1 Failure analysis of the jaw crusher and its components is based on life ... The solution is the installation of high performance crushers and the optimization of the maintenance and repair system ...

获取价格

Dynamics Analysis of Compound Pendulum Jaw Crusher with

2023/10/20 Previous dynamic studies of the complex pendulum jaw crusher neglected the bearing clearance between the eccentric shaft and the moving jaw, which is crucial for analyzing the effect of bearing clearance on the dynamic performance of the crusher. By employing the Lagrange multiplier method, a dynamic model considering the bearing clearance of the

获取价格

(PDF) Design and Analysis of Swing Jaw Plates of Jaw Crusher

IJMER. Abstract: Crushers are major size reduction equipment used in mechanical , metallurgical and allied industries which crushes different types of soft and hard materials. swing jaw plates are takes direct part into this oprations.hence the design and analysis are very important .This paper focuses on review of a work carried out by researchers on analysis of swing jaw plate i.e.

获取价格

Global Track-mounted Jaw Crushers Market Analysis: Trends

2024/11/9 Track-mounted Jaw Crushers Market: Efficiency Meets Innovation The dynamic landscape of track-mounted jaw crushers is characterized by an increased focus on efficiency, innovation, and resource ...

获取价格

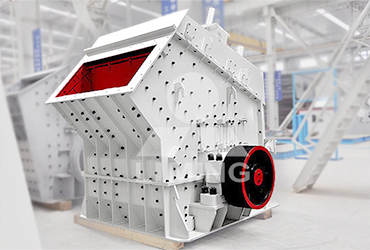

Jaw Crusher Advantages and Disadvantages - Maden Crushing

A Comprehensive Analysis: Jaw Crusher Advantages and Disadvantages Jaw crushers are widely used in the mining and construction industry due to their ability to crush hard materials efficiently. They are a primary choice in crushing applications involving various materials like ores, concrete, and more.

获取价格

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022/9/20 A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine ...

获取价格

Energy consumption of a laboratory jaw crusher during normal

2023/12/1 This paper presents the measurement and analysis of energy consumption of a laboratory jaw crusher during concrete recycling. A method was developed to estimate the power requirements of a lab-scale jaw crusher. ... Influence of some rock strength properties on jaw crusher performance in granite quarry. Mining Science and Technology (china), 20 ...

获取价格

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported

获取价格

Design and Analysis of Swing Jaw Plates of Jaw Crusher

Keywords: Finite Element Analysis; Swing Jaw Plates; Jaw Crusher; I. INTRODUCTION Jaw crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws (feed opening). Primary jaw crushers are typically of the

获取价格

Failure analysis of jaw crusher and its components using ANOVA

Therefore, to minimize sudden failures, proper brainstorming needs to be done to improve performance and operational reliability of jaw crushers and its components. Though traditional maintenance practices exist in mineral processing plants, a methodical approach to analyse the failure rates of components is imperative for improving operational ...

获取价格

Estimate Jaw Crusher Capacity - 911Metallurgist

2016/2/18 The capacities are based on the crusher receiving full, continuous feed of clean, dry, friable stone weighing 100 lb/cu ft. These capacity tables show several significant differences between the two common types of primary crushers. A jaw crusher has a wider range of settings—generally, a maximum of two to three times the smallest setting.

获取价格

Jaw Crusher - an overview ScienceDirect Topics

Crushers. Barry A. Wills, James A. Finch FRSC, FCIM, P.Eng., in Wills' Mineral Processing Technology (Eighth Edition), 2016 Jaw-crusher Construction. Jaw crushers are heavy-duty machines and hence must be robustly constructed. The main frame is often made from cast iron or steel, connected with tie-bolts. It is commonly made in sections so that it can be transported

获取价格

Design and Analysis of Swing Jaw Plates of Jaw Crusher

Keywords: Finite Element Analysis; Swing Jaw Plates; Jaw Crusher; I. INTRODUCTION Jaw crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws (feed opening). Primary jaw crushers are typically of the

获取价格

Failure analysis of jaw crusher and its components using ANOVA

Therefore, to minimize sudden failures, proper brainstorming needs to be done to improve performance and operational reliability of jaw crushers and its components. Though traditional maintenance practices exist in mineral processing plants, a methodical approach to analyse the failure rates of components is imperative for improving operational ...

获取价格

Estimate Jaw Crusher Capacity - 911Metallurgist

2016/2/18 The capacities are based on the crusher receiving full, continuous feed of clean, dry, friable stone weighing 100 lb/cu ft. These capacity tables show several significant differences between the two common types of primary crushers. A jaw crusher has a wider range of settings—generally, a maximum of two to three times the smallest setting.

获取价格

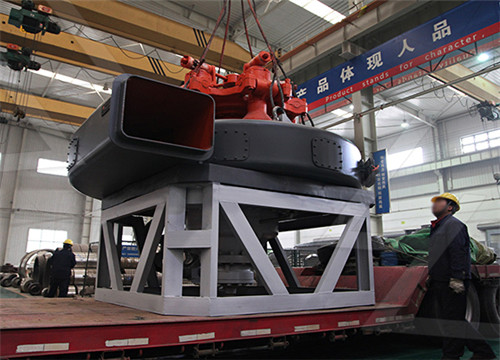

Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw ...

2022/12/24 Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher.

获取价格

Jaw crusher kinematics simulation and analysis - IJRES

performance parameters of dual-chamber jaw crusher is relatively certain that the dual-chamber jaw crusher machine performance, is a far-reaching development a new type of potential. 2.2 The overall design ... Song Wei, Ding Kaijun, based on the motion of jaw crusher ADAMS working device analysis, mining machinery Vol.31 06, 2010, (2)

获取价格

Dynamics Analysis of Compound Pendulum Jaw Crusher with

2023/10/22 Abstract: Previous dynamic studies of the complex pendulum jaw crusher neglected the bearing clearance between the eccentric shaft and the moving jaw, which is crucial for analyzing the effect of bearing clearance on the dynamic performance of the crusher. By employing the Lagrange multiplier method, a dynamic model considering the bearing

获取价格

Evaluation of blast fragmentation effects on jaw crusher throughput

2021/9/21 As a second step of the jaw crusher performance observations, crushing times of the jaw crusher were measured and recorded for each truckloads of blasted rock. ... In order to establish a relationship between the size distribution and the K07 (1100x850) jaw crusher, statistical regression analysis was carried out and empirical equations were ...

获取价格

[PDF] Computer aided design of jaw crusher Semantic Scholar

2010/5/13 Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipments in mechanical and mining industries. As jaw crushers break minerals ores of high strength and the economy of many industries depends on its performance; it is essential to improve the efficiency of the present design. The kinematic analysis of single

获取价格

Assessing the energy efficiency of a jaw crusher - ScienceDirect

2014/9/1 The analysis will concentrate on jaw crushers as typical and widely used comminution process equipment. ... Jaw crusher performance contour plots. 3.2. DEM. A DEM is a family of computational methods widely used for simulating flows of powders or granular materials. These techniques simulate systems consisting of discrete particles where ...

获取价格

Development of a New Generation High Crushing Capacity Jaw Crusher

2023/12/31 The forces on the crusher jaw and bearings, the crusher body geometry and crusher material (via fatigue analysis), and the dynamic performance of the system (via vibration analysis of the carrier ...

获取价格

SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

2017/3/4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

获取价格

Failure rate analysis of Jaw Crusher: a case study - ResearchGate

2019/1/2 Failure of crusher components has considerable influence on the productivity of a crushing plant. In order to improve performance and operational reliability, its critical components are needed to ...

获取价格

Design and Finite Element Analysis of Swing Jaw Plate of Jaw Crusher ...

IJMER. Abstract: Crushers are major size reduction equipment used in mechanical , metallurgical and allied industries which crushes different types of soft and hard materials. swing jaw plates are takes direct part into this oprations.hence the design and analysis are very important .This paper focuses on review of a work carried out by researchers on analysis of swing jaw plate i.e.

获取价格- تصنيع مزدوج كسارة الفك

- الذهب خطة غسل الكتيبات آلة

- علبة تكسير الزيت

- طاحونة الكرة الجافة طحن المواد رمح ترس

- عدسة بصرية طحن معدات قياس الصورة

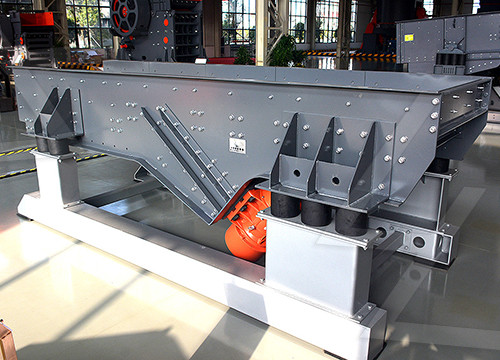

- النموذج طاحونة الاهتزاز

- شركات التعدين تسعى المساحين الكمي

- كاشف المعادن لمحطة كسارة

- تخطيط كامل لآلة كسارة الحجر

- سحق نظام قمع غبار النبات

- كسارة في دولوريس كويزون

- مزادات علنية للمعدات الثقيلة

- سطل معدن برای بیل

- سحق خام الفضة الاعمال المنزلية

- ما هي المعدات التي تحتاجها في المحجر

- ترنيمة طاحونة قديمة

- آلات سحق vsi المطرقة العمودية

- نوعية جيدة سحق شاشة المحمول

- شاشة الاهتزاز لآلة التعدين الخطية من سلسلة ZK

- بيع قطع غيار مكعب q r920

- مطحنة غريفين

- نسبة التخفيض في حجر محطم

- سهولة التعامل مع سعر كسارة الفك الجديد

- یخ ابزار سنگ شکن

- بنتونیت تولید تجهیزات تصاویر

- 3 مطحنة ختم للبيع في babwe

اقرأ أكثر

اقرأ أكثر