اطلب اقتباس

jaw crushers as secondary crusher

Primary Crusher vs. Secondary Crusher: Understanding

2023/2/28 While primary crushers are responsible for breaking down larger rocks and stones into smaller particles, secondary crushers are used to further refine these particles into the desired size and shape. The primary crusher is

获取价格

Understanding Types of Jaw Crusher: A Comprehensive

2024/2/6 PEX / PE Jaw Crushers. PE and PEX jaw crushers have diverse roles in the breaking down of rocks and ores. PE crushers, often chosen for primary crushing jobs, are built strong enough to take in big chunks of

获取价格

Downstream Crushing Options for Secondary, Tertiary and

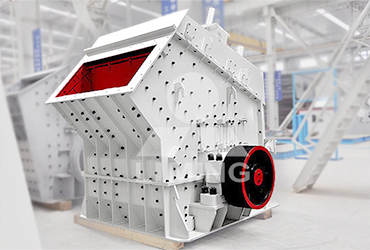

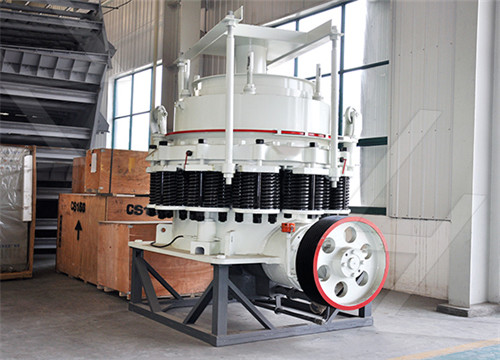

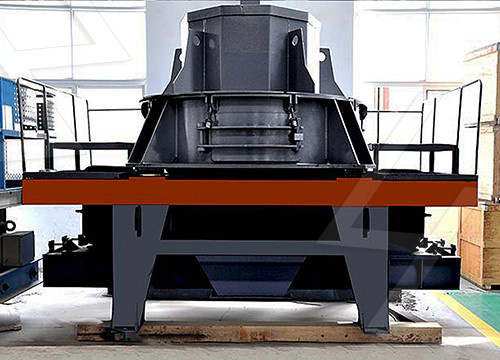

Types of Secondary CrushersTypes of Tertiary and Quaternary CrushersChoosing The Right Secondary CrusherSecondary crushers typically include (but are not limited to) Cone Crushers, Horizontal Shaft Impactors, Hammermills and Roll Crushers. Occasionally, a Jaw Crushermay be applied as a secondary crusher. Cone Crushers Cone Crushersare compression-type crushers, which reduce material as it advances downward through the chamber (with the help of gravit...

Understanding the Difference Between Primary and

2023/2/28 The crushing process involves the use of crushers to break down rocks and stones into smaller sizes. The primary crusher is used to reduce the size of the initial rocks, while the secondary crusher further breaks down

获取价格

The Complete Guide to Primary Crushing, Secondary

2023/2/28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages

获取价格

Types of Crushers: What You Need to Know

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are

获取价格

What Is A Jaw Crusher - MEKA

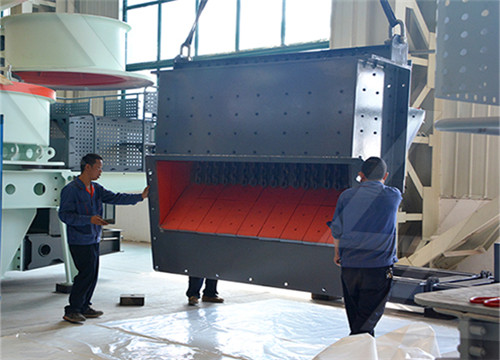

Secondary Crushing. This is the second stage of crushing. Feed size, ... The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6.

获取价格

Jaw Crushers - AGGRETEK Jaw Crushers for aggregate

Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly used crushers due to

获取价格

Concrete aggregates properties crushed by jaw and impact

2019/1/1 Particle size distribution curves of recycled aggregates from concrete pavement crushed by jaw and impact crushers. The jaw crusher produced 85% coarse aggregates

获取价格

Types of Crushers: Choosing the Right One for Each

2024/7/17 1. Primary crushing equipment. Primary crushing is the first stage of the stone crushing process. At this stage, raw materials extracted through blasting or mining are crushed to a size suitable for conveyor

获取价格

What is a Primary Crusher? - Machinery Partner

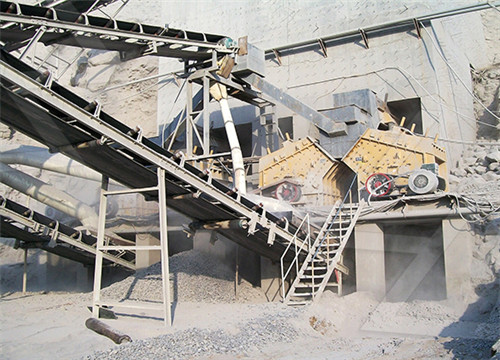

Primary jaw crusher and secondary impact crusher working together in a plant set-up. The most common primary crusher is a jaw crusher, but, there are many other types including gyratory and cone crushers. We will talk about them all

获取价格

Impact Crushers - Secondary - McLanahan

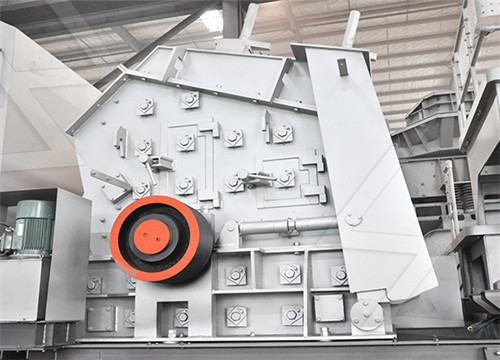

The NGS Impact Crusher is extremely versatile. The most common application involves taking primary-run limestone from either a Jaw Crusher or impact breaker and reducing it into a construction grade aggregate. However, with

获取价格

Jaw Crusher Basics in 3 Minutes-SBM Industrial Technology Group

2024/8/20 It is well known that in the production line of crushing, sand making and ore dressing, jaw crusher is used for coarse crushing as a primary crushing equipment (fine jaw crusher can be used for medium or fine crushing), while impact crusher is usually used for medium or fine crushing as a secondary or tertiary crushing equipment. 3.

获取价格

Eagle Jaw Crushers Eagle Crusher

Eagle Jaw Crushers eliminate premature failures to provide years of component life, durability, and reliability for your crushing applications. ... Eagle 2036 Jaw Crusher; Eagle 3242 Jaw Crusher; ... Bare Equipment. Ultramax® Impactors; Eagle Jaw Crushers; Hammermills; Secondary Plants. 500-05 CVSS; 1200-25 OCSS; Specialty Systems. The MaxRap ...

获取价格

Understanding Types of Jaw Crusher: A Comprehensive Guide

2024/2/6 Jaw crushers in the secondary stage are geared to give you a finer crush, and they’re usually more compact than their primary counterparts. ... The design of the Dodge jaw crusher provides a crushing action that minimizes wear on the jaw plates, making it suitable for applications where abrasive materials are not the primary focus. ...

获取价格

High efficiency crushing – FLS jaw crushers -

Our EB Pro range of jaw rock crushers includes: Jaw Crusher EB 20-15 Pro with a capacity range of 600 – 1,600 tph. Jaw Crusher EB 16-12 Pro with a capacity range of 400 – 1,200 tph. Jaw Crusher EB 14-11 Pro with a capacity range of 300 – 950 tph.

获取价格

Crushers: 5 types and their main failures - Dynamox

2024/4/19 Thus, the material is transformed into particles suitable for transport on conveyor belts and to feed the secondary crushing (reducing blocks from 300 – 100 mm to 100 – 38 mm), the semi-autogenous mill (SAG), or to form the stockpile for leaching. ... The jaw crusher is used in primary crushing and is therefore usually installed near the ...

获取价格

Deepa Jaw Crusher - Secondary - deepacrushers

Deepa Jaw Crusher - Secondary Deepa Secondary Crushers are extra-large with wide mouth opening to take in bigger size feed materials. The conventional theory of 1:6 reduction ratio for jaw crushers is surpassed in Deepa Secondary Crushers. Deepa Secondary crushers has very high reduction ratio of upto 1:12.

获取价格

Single Toggle Jaw Crusher - thyssenkrupp Polysius

For crushing middle hard to hard and abrasive materials in primary and secondary crushing applications for low and high capacities. Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate.

获取价格

Secondary Crushing 101: Everything You Need to Know - JXSC

2024/3/25 Primary Crusher: Jaw crushers, Gyratory crushers: Secondary Crusher: Cone crushers, Impact crushers, Gyratory crushers ... The feed size means the biggest piece the crusher can crush. Secondary crushers usually can crush pieces that are 6 to 10 inches big (150 to 250 mm). This shows why crushing things smaller first is important.

获取价格

Jaw Crushers - McLanahan

McLanahan’s Universal Jaw Crusher produces more spec material at a lower cost per ton and ensures continuous crushing action with less abrasive wear. ... They are used for primary and sometimes secondary size reduction. Applications. Aggregates; CD Recycling; ... Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first ...

获取价格

Types of Crushers: What You Need to Know Machinery Partner

Gyratory Crusher Secondary crushing equipment. After materials go though their first round of crushing, they are fed into a secondary crusher to be broken down further. The average input size for a secondary crusher ranges from 13" to 4" during this stage. Secondary crushing is especially important for making graded material that is going on to ...

获取价格

Exploring Jaw Crusher Efficiency Kemper Equipment

Jaw Crusher Reduction Ratio. Either an 8-to-1 or 6-to-1 ratio should be the target reduction ratio for maximum jaw crusher efficiency. This setting typically provides an ideal P80 factor—when 80% of crushed material produced by primary crushing will pass screening after processing.

获取价格

Jaw Crushers - Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. ... mining and recycling in

获取价格

Jaw Crushers - McLanahan

McLanahan’s Universal Jaw Crusher produces more spec material at a lower cost per ton and ensures continuous crushing action with less abrasive wear. ... They are used for primary and sometimes secondary size reduction. Applications.

获取价格

Types of Crushers: What You Need to Know

Gyratory Crusher Secondary crushing equipment. After materials go though their first round of crushing, they are fed into a secondary crusher to be broken down further. The average input size for a secondary crusher ranges from 13" to 4"

获取价格

Exploring Jaw Crusher Efficiency Kemper Equipment

Jaw Crusher Reduction Ratio. Either an 8-to-1 or 6-to-1 ratio should be the target reduction ratio for maximum jaw crusher efficiency. This setting typically provides an ideal P80 factor—when 80% of crushed material produced by primary

获取价格

Jaw Crushers - Astec

Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability. ... mining and recycling in

获取价格

Secondary Plants - Eagle Crusher

Eagle 2036 Jaw Crusher; Eagle 3242 Jaw Crusher; Eagle 3260 Recycle Jaw Crusher; Bare Equipment. Ultramax® Impactors; Eagle Jaw Crushers; Hammermills; Secondary Plants. 500-05 CVSS; 1200-25 OCSS; Specialty Systems. The MaxRap® System; MaxRap® 25 Portable; Jaw/Impactor System; Pre-Owned Equipment

获取价格

What Is an Impact Crusher and What Can It Do for You?

2021/1/10 An impact crusher, or impactor, is one of several types of crushing machines, including jaw crushers, hammermills, and cone crushers, that is manufactured for the purpose of processing raw materials, like concrete or asphalt, among many others, to reduce them in size. ... From soft rock to hard rock—as a primary crusher or secondary crusher ...

获取价格

Crushers - VIRIDIS Engineering Sdn Bhd

Crushers Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations. Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output []

获取价格

Secondary Jaw Crusher Manufacturer from Navi Mumbai

The offered range of Jaw Crushers is mainly suitable for primary and secondary crushing.These products are appreciated fore easy maintenance, easy installation debugging and low power consumption. Our Jaw Crushers are in conformation with international norms and standards.

获取价格

Fine Jaw Crusher Pex-250X1200 (PEX1047) for Secondary Crushing

The most versatile primary crusher. Kinglink's Series jaw crushers are most commonly used as primary crushers, to make the first step of size reduction. In some cases the jaw crushers is used to produce final end product but in most cases the jaw crusher is used to prepare the feed for the secondary crusher in a crushing and screening process.

获取价格

Jaw Crusher Crushing Plant Hard Rock Mining Equipment DOVE

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPa.DOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration.. Designed with optimum cavities and

获取价格

JAW CRUSHERS - Maden Crushing Screening

Jaw crushers are used as the most important option in primary crushing stage especially for medium hard and hard rocks. There are also secondary type jaw crushers designed for secondary crushing of hard materials. The eccentric shaft for jaw crusher is made of special alloy steel (Mn. Cr. Ni. Mo. ) Hydraulic setting adjustment system

获取价格

Different Types Of Crushers Machine Of Primary,secondary

Secondary Crusher, Tertiary Crusher, Quaternary Crusher For Fine crushing circuits are more challenging than primary crusher. Secondary Crusher, Tertiary different installation and the crusher. liming cone crushers have three types

获取价格

Jaw Crusher - Jaw Crusher Mannufacturers AGICO Cement

Jaw crusher is suitable for crushing all kinds of ores and rocks whose compressive strength limit is less than 250 mpa. It is mainly used as the primary crusher or secondary crusher in cement plant and concrete industries. The jaw crusher is divided into three types according to the width of the feeding port: large type, medium type, and small type.

获取价格

5 Common Questions about Jaw Crushers Answered

2019/5/30 Jaw crushers have been around for nearly 200 years and are one of the most “historic” crusher types. Because of this, jaw crushers have undergone many technological advances through the years ...

获取价格- كسارة الصخور الصلبة لتعدين النحاس للبيع

- حار بيع تأثير محطم آلة سحق الحجر مع ISO9001: 2008

- كسارة المطرقة الأسمنتية ذات حجم الإخراج الجيد المشهورة في صناعة الأسمنت

- بناء شاشة ذهبية دوارة

- مطحنة للفحم العراقي

- wieght حساب 800mm الحزام الناقل

- الذهب الإيطالي آلة الرمال والحجر موضوع القرارات الخاصة بك صغيرة

- عقد الإيجار لكسارة الحجر

- معدات إنتاج رمل الكوارتز للبيع

- حزب العمال مانتيمين تعدين النحاس معدن النحاس

- استخدام stonesand كبديل للأسمنت

- المهنية محطم إنتاج مطرقة

- مراقبة الغبار للتأثير كسارات الفجيرة

- كيفيت صناعت الشعر على الوجنات والشارب

- چرخ توپ معدنی

- بنا شركة معدات ثقيلة

- كسارة دنفر رول

- عمل المغذيات في معدات التكسير

- Harga chakki atta komersial

- طاحونة الكرات المختبرية المحمولة لتعدين الخام

- مصنع التكسير والغربلة المحمول Fintec 1107

- مصنع معدات تعدين الاسمنت في كوريا

- المطاحن الجبسيه الطرد المركزي

- سنگ معدن مواد معدنی پردازش نقره ای

- الصناعات الباكستانية باستخدام الكسارات الفك

- جودا منجم الحديد الشرقي

اقرأ أكثر

اقرأ أكثر