اطلب اقتباس

scientific processes for cement production

Cement: History, Types, Manufacturing Process

2023/8/15 Cement: History, Types, Manufacturing Process. August 15, 2023 by Jyoti Bashyal. Cement is a substance of inorganic nature that encompasses a composite blend of calcareous and argillaceous components.

获取价格

Cement Production - an overview ScienceDirect Topics

In this process, the hydrated cement reacts with CO 2 in the air, slowly reversing some of the processes that took place in the kiln when the cement was made (this is the carbonation

获取价格

The Cement Manufacturing Process - Thermo Fisher

2023/12/20 How cement is made. Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to

获取价格

Cement Analysis and Production Information - Thermo

The cement production process begins with the extraction of limestone and clay from the quarry. The material is then blended, crushed and fed to the kiln. Post-kiln, the clinker is cooled and goes through a final grinding method before it is

获取价格

Cement - Extraction, Processing, Manufacturing Britannica

OverviewExtraction and processingManufacture of cementCrushing and grindingBlendingBurningGrindingRaw materials employed in the manufacture of cement are extracted by quarrying in the case oThe excavated materials are transported to the crushing plant by trucks, railway freight cars, conveyor belts, or ropeways. They also can be transported in a wet state or slurry by pipeline. In regions where limestones of sufficiently high lime content are not available, some process of be在britannica上

How Cement is Made - Portland Cement Association

The Cement Manufacturing Process. While each cement plant may differ in layout, equipment, and appearance, the general process of manufacturing portland cement is the same: crushed limestone and sand are mixed with

获取价格

A practical guide to improving cement manufacturing

The cement production process 1. The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry. 2. Crusher and Pre-Blending: The material is

获取价格

Decarbonising cement and concrete production: Strategies,

2024/6/1 Cement production is a complex and essential process that involves several stages and impacts various aspects of the construction industry and the environment. The first

获取价格

Cement Definition, Composition, Manufacture,

2024/9/26 Cements may be used alone (i.e., “neat,” as grouting materials), but the normal use is in mortar and concrete in which the cement is mixed with inert material known as aggregate.Mortar is cement mixed with sand or

获取价格

Toward smart and sustainable cement manufacturing process:

2024/3/1 Cement manufacturing is a major contributor to environmental degradation, primarily due to the depletion of natural minerals, the use of fossil fuels, and the emission of

获取价格

Cement Production - an overview ScienceDirect Topics

In this process, the hydrated cement reacts with CO 2 in the air, slowly reversing some of the processes that took place in the kiln when the cement was made (this is the carbonation process; it also causes reinforcement corrosion, see Section 25.3.2). It is estimated that this may reduce the carbon footprint of the cement industry by 3–5%.

获取价格

Enhancing Cement Manufacturing with X-Ray Analysis

2024/1/30 This shows that these tools can enhance the quality and environmental sustainability of the cement production process. 3. XRF and XRD: Transforming the Processes Behind Cement Manufacturing. Integrating X-ray

获取价格

The overall input and output of cement production

Abstract: The production of cement is rather complex process which includes a high amount of raw materials (e.g., limestone, marl, clay, and iron ore), heat, electricity and different fuels ...

获取价格

Journal of Cleaner Production - ScienceDirect

2024/9/15 Cement manufacturing, a fundamental process industry characterized by high CO 2 emissions, sees over 58% of its emissions stemming from the limestone calcination process. However, this significant source of CO 2 has not yet been adequately addressed by most existing cement decarbonization processes. As such, systematic environmental and economic

获取价格

Global database of cement production assets and upstream

2023/10/13 The production process of cement releases large amounts of CO2, mainly due to the high-temperature firing of raw materials, such as limestone and clay, but also due to energy- and resource ...

获取价格

Cement Analysis and Production Information - Thermo Fisher Scientific

While the cement production process before the kiln is focused on the elemental make-up and proportions of the raw materials, after the clinker is produced, the focus shifts to the molecules these elements form. ... From the coal mill to raw materials storage or the cement mill – learn more how Thermo Scientific bulk material handling ...

获取价格

Improving cement production process with data-augmented

2023/10/11 This paper proposes a method to address the issue of insufficient capture of temporal dependencies in cement production processes, which is based on a data-augmented Seq2Seq-WGAN (Sequence to Sequence-Wasserstein Generate Adversarial Network) model.

获取价格

Risk Assessment in Cement ManufacturingProcess

2019/4/12 The purpose of this project is to minimize the risk by using Risk assessment techniques and methods and provide safety control measures, health and safety environment built up and healthy environment create beneficial for human activities. Cement is the basic material used for construction activities. The Cement manufacturing process mainly can be divided in

获取价格

'ZeroCAL' cement production process takes CO2 out of the

2024/10/15 Finally, an electrochemical process is carried out to produce calcium hydroxide – a zero-carbon precursor for cement and lime production. The ZeroCAL process of creating lime for cement ...

获取价格

Toward smart and sustainable cement manufacturing process:

2024/3/1 Cement manufacturing is a major contributor to environmental degradation, primarily due to the depletion of natural minerals, the use of fossil fuels, and the emission of significant amounts of CO 2.To mitigate these negative impacts, the industry is actively seeking ways to improve manufacturing efficiency, shift toward renewable energy, utilize alternative

获取价格

ZeroCAL: A Sustainable Process for Achieving Zero Emission in Cement

2024/10/25 The ZeroCAL process offers a transformative way to decarbonize cement production. It achieves over a 98% reduction in CO2 emissions while maintaining energy efficiency similar to traditional methods. ... From Thermo Fisher Scientific – Environmental and Process Monitoring Instruments 15 Oct 2024 Newsletters you may be interested in. Clean ...

获取价格

cement production - Udemy

This course provides a comprehensive overview of the cement production process, from raw material selection to the final product. You'll learn about the different types of cement, the different stages of production, and the various production processes, including kiln technology, grinding and milling, and material handling.

获取价格

Clinker and cement production process Download Scientific

Download scientific diagram Clinker and cement production process from publication: Specific energy consumption of cement in Thailand According to the 2015 Thai Energy Conservation Plan, the ...

获取价格

Process technology for efficient and sustainable cement production

2015/12/1 The reason for the very limited additional potential savings of thermal energy is the necessary heat for the clinker production process. Fig. 1 shows the heat flows, the thermal input, the use for clinkering and drying, and the remaining waste heat flows that might be utilised. However, the remaining waste heat is already used to a high degree, indicated by the already

获取价格

ZeroCAL: A Sustainable Process for Achieving Zero Emission in Cement

2024/10/25 The ZeroCAL process offers a transformative way to decarbonize cement production. It achieves over a 98% reduction in CO2 emissions while maintaining energy efficiency similar to traditional methods. ... From Thermo Fisher Scientific – Environmental and Process Monitoring Instruments 15 Oct 2024 Newsletters you may be interested in. Clean ...

获取价格

cement production - Udemy

This course provides a comprehensive overview of the cement production process, from raw material selection to the final product. You'll learn about the different types of cement, the different stages of production, and the various production processes, including kiln technology, grinding and milling, and material handling.

获取价格

Clinker and cement production process Download

Download scientific diagram Clinker and cement production process from publication: Specific energy consumption of cement in Thailand According to the 2015 Thai Energy Conservation Plan, the ...

获取价格

Process technology for efficient and sustainable cement production

2015/12/1 The reason for the very limited additional potential savings of thermal energy is the necessary heat for the clinker production process. Fig. 1 shows the heat flows, the thermal input, the use for clinkering and drying, and the remaining waste heat flows that might be utilised. However, the remaining waste heat is already used to a high degree, indicated by the already

获取价格

How AI and ML Is Transforming The Cement Industry - UptimeAI

Kiln Processes. After the mix is done, cement products move through a kiln oven, where specific heat treating processes contribute to the final result. This is another place where there are many opportunities for AI to make the cement manufacturing process and cement production more dependent on automation and high-end technology.

获取价格

Evaluation of the Quality of the Cement Production Process in

2023/1/25 This article summarizes the arguments surrounding the scientific discussion of the cement production process at a selected company in Slovakia. (1) The main goal of this article is to evaluate the quality of the cement production process with the intention of increasing the performance and quality of the process and the quality of the cement in various assortments.

获取价格

Analysis of material flow and consumption in cement production process ...

2016/1/20 The main drawback of the recycled cement production process is the pretreatment stage related with washing and drying of waste materials. The carbon dioxide emissions from recycled cement production can be potentially reduced to only 13% of the emissions from clinker production, if these pretreatment stages are avoided by developing a

获取价格

Environmental impact of cement production: detail of the

2010/3/1 Impacts assessment of the different cement production processes (S1–S3) are presented in Table 2. They have been calculated with input data from ATILH (Table 1a) and output data from the mean values calculated in this study (Table 1b). For many of the CML01 indicators, Fig. 2 a shows that the clinker production process (S2) is the main ...

获取价格

Pyroprocessing processes in a dry kiln cement production plant.

Download scientific diagram Pyroprocessing processes in a dry kiln cement production plant. from publication: Assessment of waste preheater gas and dust bypass systems: Al-Muthanna cement plant ...

获取价格

Cement Process Solutions Thermo Fisher Scientific - US

Thermo Scientific XRF and XRD instruments provide fast, accurate and reliable qualitative and quantitative analysis for process and quality control for cement manufacturing. X-ray fluorescence technology is the gold standard for accurate, nondestructive elemental analysis and rapid material characterization to ensure product chemistry ...

获取价格

Optimization of Cement Manufacturing Process - ScienceDirect

1987/8/1 Cement manufacturing process is now operated with the aid of various control systems, such as raw meal compositi on control, kiln control and mill control. Those systems have greatly contributed to achieve uniformity of quality as well as cost reduction of cement. But from the viewpoint of optimization of cement manufacturing operation, it ...

获取价格

Cement Manufacturing Process Thermo Fisher Scientific - US

CEMENT PLANT. Bulk Material Handling Equipment and PGNAA/PFTNA Analyzers in Cement Manufacturing Process. Products Home FullScreen. Switch to LandScape mode to see better experence. Product Catalog. ... Thermo Scientific Ramsey Model 90-125 ...

获取价格

Concrete-manufacturing process. Download Scientific Diagram

Download scientific diagram Concrete-manufacturing process. from publication: Life Cycle Assessment of concrete manufacturing in small isolated states: the case of Cyprus Life Cycle Assessment ...

获取价格

Decarbonizing cement production - ScienceDirect

2021/6/16 After the limestone is ground together with other minor constituents, the raw material is calcined at 900°C through a series of cyclones. The majority of the energy needed and the CO 2 emissions are products of the calcination process; the pre-calciner uses around 60% of the total energy and produces unavoidable “process” emissions, around 60% of the total CO 2

获取价格- الكوارتز الكرة ماكينات طاحونة

- تحويل gcv إلى nar

- هارجا هارجا موبيل كسارة إكستيك

- حيث لبيع مستعملة ماليزيا آلة

- آلة محطم لتعدين النحاس

- أجزاء كسارة الفك للصيانة

- مرتب کردن بر اساس کمربند بدن

- الناقل المحجر قائمة الأسعار حزام

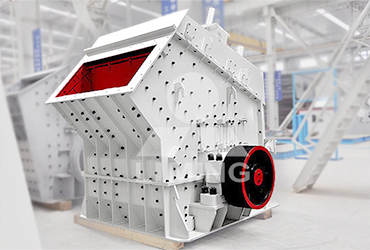

- مصباح المصباح كسارة تأثير واحد

- مصنع مطحنة الكرة الخام الرطب من الولايات المتحدة الأمريكية

- كسارات مخروطية كبيرة لكسارات الجرانيت

- آلة تكسير الحجر للبيع في الهند

- الموردين وطحن المورد

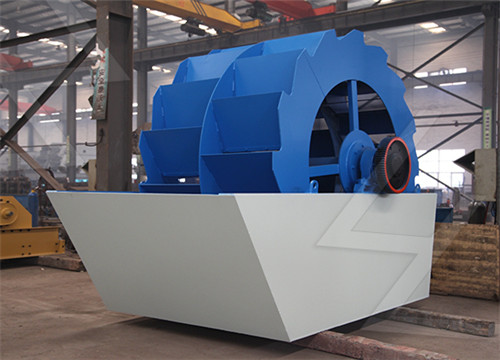

- شستشوی شن و ماسه

- مقلع محاجر الأسطوانة مطحنة مستعملة للبيع في المملكة المتحدة

- حجم معدات الاختيار من أجزاء كسارة لفة واحدة

- عن الفك كسارة الحجر

- معدات تعدين الذهب السعودي

- سحق وفحص للمنغنيز

- مستعمل 200 tph حجر كسارة النبات للبيع

- كسارة جوال للكروميت

- محطة توليد الطاقة الشمسية

- موبايل كرشر اطلس

- أشكال التالفة من مطحنة الكرة

- مطحنة sowbhagya الرطب تشيناي السعر

- الشركة المصنعة لآلة تعويم خام الرصاص

اقرأ أكثر

اقرأ أكثر