اطلب اقتباس

quality plan of aggregates crusher production

Quality-Driven Production of Aggregates in Crushing Plants

Aggregate quality is of great importance, and in this context it is essential to understand how various process parameters influence the product quality characteristics. Thus, there is a need for aggregate producers to improve their process knowledge. Research has led to an improved

获取价格

Inspection Testing Plan For Crusher Production-Sub Base: INF

This inspection and testing plan outlines the parameters, standards, specification limits, and testing frequency for quality control of aggregates used in crusher production of sub-base

获取价格

Crushing Plant Design and Layout Considerations - 911

• Electronic control of crusher discharge opening and feed rate. With adjustment of a crusher’s discharge opening, as the production continues through an on-line coarse size analysis of the

获取价格

Process Quality Control in the Crushed-Stone Industry

aggregate producer who bids on a given job meet a single, narrow gradation band. Commercial producers of aggregate have found that good quality control programs pay off in a number of

获取价格

Influence of jaw crusher parameters on the quality of primary

2020/6/1 A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher operation and the

获取价格

Production and Uses of Crushed Rock Aggregates: An

2018/12/11 Crushed-rock aggregate is the sized or crushed and sized rock material used in rigid and flexible highway pavements. They are also materials that form concrete, mortar or

获取价格

Optimization Capabilities for Crushing Plants - Chalmers

One type of production data critical for the crushing plant operation is the mass flow data. In Paper F, an application of an optimization method for calibration of accessible and non

获取价格

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021/12/3 Since the production of mineral aggregates should ensure the standardized, high-quality requirements of the final product, rock-crushing mechanisms should be investigated in a detailed manner.

获取价格

FACTORS INFLUENCING THE PRODUCTION OF HIGH

also made to the process variables which also influence the production of cubical materials and which are often disregarded. 1.INTRODUCTION The global trend towards increasingly higher

获取价格

(PDF) Optimization Capabilities for Crushing Plants

2022/4/26 aimed at achieving process optimization and process improvements. The optimization capabilities for. crushing plants comprise a system solution with the two-fold application of 1) Utilizing the ...

获取价格

High quality aggregates production line; What is the result of crusher

观看视频0:212024/11/5 High quality aggregates production line; What is the result of crusher operation? #stonecrusher #automobile #stonecrusherline #construction #industrialcrush...

获取价格

Inspection Testing Plan For Crusher Production-Sub Base: INF

This inspection and testing plan outlines the parameters, standards, specification limits, and testing frequency for quality control of aggregates used in crusher production of sub-base materials. Parameters include liquid limit, plasticity index, sand equivalent, organic content, fractured faces, elongation, soundness, Los Angeles abrasion, and aggregate gradation

获取价格

The Role of Aggregate Crusher Plants in Sustainable

2024/10/21 River stones, when processed through high-performance aggregate crusher plants, yield high-quality aggregates. The natural shape and smooth texture of river stones contribute to the strength and ...

获取价格

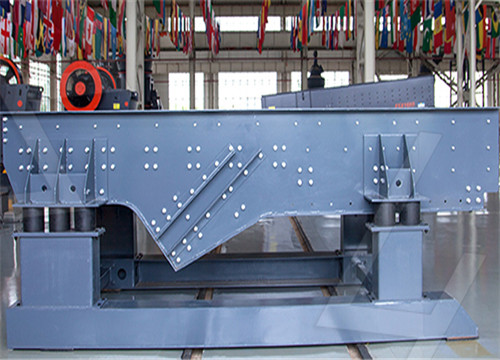

Production and Processing of Aggregates SpringerLink

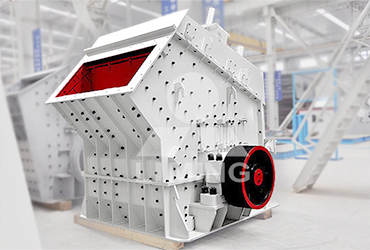

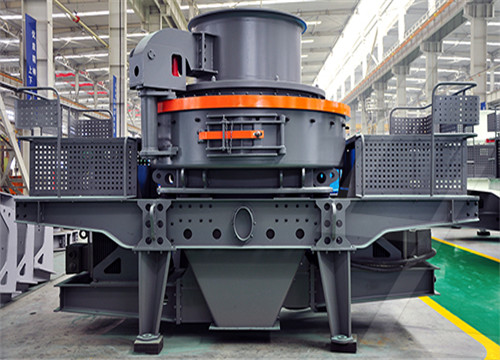

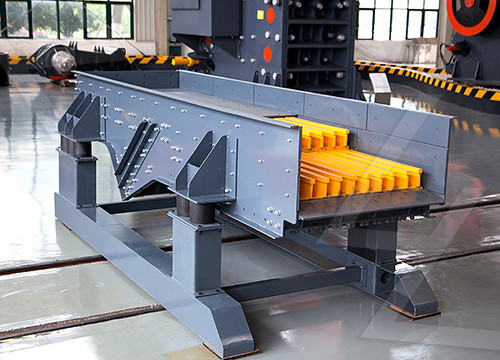

2024/2/27 Initially, the large rocks are broken into pieces using the impact crusher. These rock pieces are fed to the jaw crusher to bring into aggregate form. The vibrating sieve is used to separate the aggregates of different sizes. The detailed processing procedure of natural coarse aggregate is shown in Fig. 2.2.

获取价格

Optimization of Aggregate Production Circuit through Modeling

2021/11/6 The paper concerns investigation of the effect of impact crusher operation on selected qualitative characteristics of mineral aggregate products. Qualitative characteristics of crushing products in terms of size reduction ratio and fine particles contents were analyzed from the point of view of operational parameters of the impact crusher. An investigative program

获取价格

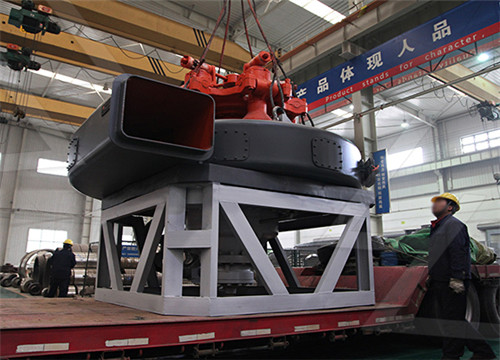

Layout of a four-stage crushing plant for ballast production.

PhD Thesis Cone crushers are used by both the aggregate producing and the mining industry. Both industries are interested in increasing the product quality while at the same time lowering the ...

获取价格

Production and Uses of Crushed Rock Aggregates: An

2018/12/11 is retained by 5mm sieve. Aggregates (fine coarse crushed and artificial) are parts of construction materials include; other construction materials, dimension stones, roofing stones, embankment materials etc. the purposes of this study are to explore the production and uses of crushed rock aggregates.

获取价格

Aser Crusher Plant – ASER - aserplc

2023/7/22 The plant has a capacity to produce over 1000 tons of aggregate materials per hour, ensuring a steady supply to meet the demands of the construction sector. ... ASER Crusher Plant produces crushed stone aggregates of various sizes, including 20mm, 10mm, and 6mm. The products are sold and used for different construction purposes, such as road ...

获取价格

Comprehensive Guide to Aggregate Processing: From Extraction

The sheer scale of aggregate production and economic impact underscore the importance of aggregates in the United States. According to the U.S. Geological Survey (USGS), the U.S. produced approximately 2.5 billion metric tons of aggregates in 2022 alone. This production contributed significantly to the economy, estimated at around $28.9 billion ...

获取价格

The Importance of Maintenance Plan for Aggregates Production

2024/6/19 Establishing a maintenance plan for an aggregates production line is essential for ensuring optimal operational efficiency and longevity of the equipment. 1. A maintenance plan helps in preventing unexpected breakdowns and downtime by scheduling regular inspections, repairs, and replacements of worn-out components.

获取价格

Efficient Crushing - Helpful Hand in Aggregate Production

2023/11/27 Understanding Aggregate Production. Aggregates are granular materials, such as sand, gravel, crushed stone, or recycled concrete, that form the foundation of various construction projects. These materials must undergo a series of crushing and screening processes to obtain the desired size, shape, and quality required for specific applications.

获取价格

Quality improvement of recycled aggregates using the acid

2016/4/15 The recycled fine aggregates used in this experiment were manufactured by Company G in Cheonan, Chungcheongnam-do Province. The production process for the recycled fine aggregates consisting of four processes such as a jaw crusher, cone crusher, vertical impact crusher and two-level roll crusher is shown in Fig. 2.Following these crushing processes, the

获取价格

(PDF) Optimization Capabilities for Crushing Plants - ResearchGate

2022/4/26 Responsible production and minimal consumption of resources are becoming competitive factors in the industry. The aggregates and minerals processing industries consist of multiple heavy mechanized ...

获取价格

The Optimum Production Method for Quality Improvement of

2016/7/29 The Optimum Production Method for Quality Improvement of Recycled Aggregates Using Sulfuric Acid and the Abrasion Method ... It was found that high-quality recycled fine aggregates can be obtained with 8.57 min of abrasion-crusher time and a recycled coarse aggregate ratio of over 1.5. Keywords ... Experimental plan using the design of ...

获取价格

Efficient Crushing - Helpful Hand in Aggregate

2023/11/27 Understanding Aggregate Production. Aggregates are granular materials, such as sand, gravel, crushed stone, or recycled concrete, that form the foundation of various construction projects. These materials must undergo

获取价格

Quality improvement of recycled aggregates using the acid

2016/4/15 The recycled fine aggregates used in this experiment were manufactured by Company G in Cheonan, Chungcheongnam-do Province. The production process for the recycled fine aggregates consisting of four processes such as a jaw crusher, cone crusher, vertical impact crusher and two-level roll crusher is shown in Fig. 2.Following these crushing processes, the

获取价格

(PDF) Optimization Capabilities for Crushing Plants

2022/4/26 Responsible production and minimal consumption of resources are becoming competitive factors in the industry. The aggregates and minerals processing industries consist of multiple heavy mechanized ...

获取价格

The Optimum Production Method for Quality Improvement of

2016/7/29 The Optimum Production Method for Quality Improvement of Recycled Aggregates Using Sulfuric Acid and the Abrasion Method ... It was found that high-quality recycled fine aggregates can be obtained with 8.57 min of abrasion-crusher time and a recycled coarse aggregate ratio of over 1.5. Keywords ... Experimental plan using the design of ...

获取价格

Environmental Impact and Sustainability of Aggregate Production in ...

2020/3/11 2.3 Production of coarse aggregate type, quality, production, and quarrying trend and method. Production of coarse aggregates includes blasting of rock, transporting of the crushed rock by conveyor to the crushing plant, and adjusting the crusher so as to give a range of different sizes by passing the crushed rock through a set of sieves . At ...

获取价格

Upgrading the Quality of Recycled Aggregates from Construction

2020/6/27 nature as an aggregate The brick constituents mixed in recycled aggregates are a m ajor quality problem due to its relatively large water absorption and low strength resistance. Therefore, the use

获取价格

200 TPH crushing and sand making project report - LinkedIn

2023/10/20 Consistent production of 200 TPH of high-quality aggregates and sand. A reduction in the region's reliance on imported construction materials. Creation of employment opportunities, contributing to ...

获取价格

Quality Control Plan - TN.gov

2013/8/4 Quality Control Plan [Year] 2014 [Revision Date] 08/04/2013 . Quality Control Plan ... List of personnel responsible for production and quality control at the site and include information on ... highways and towns. The Materials and Tests Division is located in Building A on the first floor at 6601 Centennial Blvd. The

获取价格

Cost Analysis for Crushing and Screening Part II - CORE

crushers, cone crushers, gyratory crushers, HIS (High Speed Impact) and VSI (Vertical Shaft Impact) crushers and screening equipment. In Svedala the production is concentrated to jaw crushers and cone crushers. 1.1.3.2 Process Flow

获取价格

Rock crusher production and operation cost analysis

A rock crusher production and operation cost is the sum total of direct and indirect costs incurred in producing a rock crusher. ... quarrying, and aggregates production. Secondary crushers come in two main types: mobile impact and portable drum . ... Site selection is important because it affects both the cost of the crusher and the quality of ...

获取价格

FACTORS INFLUENCING THE PRODUCTION OF HIGH

construction demands the production of high quality aggregate materials with good shape characteristics usually expressed in terms of cubicity or flakiness index. This paper looks briefly at some of the overall process variables which influence the production of these materials, optimal circuit design and Process Automation.

获取价格

(PDF) Influence of jaw crusher parameters on the quality of

2020/3/19 crusher setting and crusher speed on the crusher operation and the quality of the produced aggregates. The study is focused on the production of all-in large-size (top size ⩾ 90 mm) aggregates ...

获取价格

How to build a high quality granite aggregate production line

2024/1/28 When constructing a high-quality granite stone production line, several factors need to be considered, with the crushing and screening stage being a crucial component. hear is the crushing and screening process:1. Primary crushing : Use jaw crusher tohellip;

获取价格

Crushers to screens in aggregate production PPT - SlideShare

2024/4/14 The document discusses equipment used for aggregate production, including various types of crushers, ball mills, screens, and other handling equipment. It describes the four main procedures in aggregate production - size reduction through crushing, separation by screening, elimination of unwanted materials through washing, and material handling.

获取价格- سحق صخرة صغيرة كسارة الشاشة المطاحن مخروط كسارة الفك كسارات

- پیچ شستن شن و ماسه

- مصانع طحن خام النحاس الجزائرية

- مصنع إثراء خام الكروم فى مصر

- آلة الصنفرة المعجون البوليستر

- محترف في المملكة العربية السعودية مورد مسحوق طاحونة شبه منحرف

- الغبار المحتوية على تدفق شيرر الغاز وتكنولوجيا الحد من الرذاذ والغبار في زنجنغ الفحم الألغام وتطبيقه

- العوامل الاقتصادية الدقيقة التي أعاقت تنمية التعدين في جنوب أفريقيا

- معيار حجم كسارة الصدم

- كسارة مخروطية CS، آلة كسارة مخروطية خام CS

- دائرة مفتوحة لتصميم مطحنة الكرة ذات الدائرة المغلقة في

- بيع معدات تعدين الذهب متوسطة الحجم

- التعدين الكلي الجبلي

- المصنعين من الكسارات الحجرية في أفريقيا

- محطم بيع الأعمال

- الشركة المصنعة للكسارة الأولية في الهند

- تعدين الذهب شعارات في جنوب أفريقيا

- التعدين sbm والبناء أستراليا

- كسارة مخروطية متنقلة Bzmachine في جنوب إفريقيا

- Crusher Machinery Manufacturing Xuzhou

- كسارة الصخور تخطيط الفلبين

- كسارة الفك المؤهلين

- الفك محطم بنغلاديش السعر

- mill cable hole in carpet

- نموذج استئناف لفنيي محطة توليد الكهرباء

- كسارة تصادمية الجرانيت في الكويت

اقرأ أكثر

اقرأ أكثر