اطلب اقتباس

costs of beneficiation of nickel

Improved beneficiation of nickel and iron from a low-grade

2020/3/1 To improve beneficiation of nickel and iron from low-grade saprolite laterite with 1.29 ... content can be directly charged into electric furnace to produce austenitic stainless

获取价格

Thermo-ecological and exergy replacement costs of nickel

2014/8/1 Exergy replacement cost applied to nickel production processes. This methodology requires the identification of the nickel ores from which it is produced. In this

获取价格

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021/3/24 lateritic nickel ore: Estimated investment: 150000$ lateritic nickel ore grade: 1.29 wt% Ore beneficiation method: Wet magnetic separation and forth flotation: Concentrate content: 8.3% Recovery rate: 92%

获取价格

The Comprehensive Guide to Nickel Processing

2024/1/19 4. Beneficiation Techniques. In some cases, nickel ore may undergo beneficiation processes to improve its quality and increase the concentration of nickel. Beneficiation methods can vary depending on the

获取价格

Selection Of Nickel Ore Beneficiation Process

2024/11/11 When the nickel content exceeds 3%, it can be directly smelted and used for the production of various materials. However, when it is less than 3%, it can only enter the smelting process after the nickel ore

获取价格

Review of the past, present, and future of the

2020/7/22 Among hydrometallurgical processes for laterite processing, the HPAL process is the most effective for recovering nickel and cobalt, but high capital investment and operating costs represent a ...

获取价格

Full article: The Direct Leaching of Nickel Sulfide

2022/5/16 Beneficiation practice. Nickel sulfide ores are subjected to mineral beneficiation to reject sulfidic and non-sulfidic gangue and produce a nickel concentrate grading from 5% to 25% Ni suitable for ... Björkman, M.,

获取价格

Characterization of a Nickel Sulfide Concentrate and Its

2024/4/18 In anticipation of future demands, a comprehensive understanding of the chemical and mineralogical characteristics of nickel-bearing minerals is a prerequisite to devising effective nickel beneficiation methods. Of

获取价格

(PDF) Characterization of a Nickel Sulfide Concentrate and Its ...

2024/4/18 Of particular importance are markers in the mineralogy of the flotation concentrate that inform beneficiation strategies to improve concentrate grades, increasing both

获取价格

Analysis Of Low-Grade Copper-Nickel Ore Beneficiation Testing

2023/10/5 This analysis helps increase recycling rates, reduce operating costs and minimize environmental impact. ... The following is a typical low-grade copper-nickel ore beneficiation test process: Sample collection: First, low-grade copper-nickel ore samples from the mine must be collected. These samples should represent different parts of the ...

获取价格

(PDF) INVESTIGATION OF PROCESSING OF

2018/9/21 Nickel laterite ores account for over 60% of global nickel supply. They are the product of intensive deep weathering of serpentinites under humid tropical conditions.

获取价格

Assessment of environmental sustainability of nickel

2023/1/4 Figure 2 presents the global nickel flows in different stages, mining including nickel ore mining, beneficiation and preparation ; production focused on using nickel in battery industries, including NCA and NMC ; and

获取价格

US3711032A - Flotation of lateritic nickel ores - Google Patents

the laterites generally have been regarded as being completely refractory to beneflciation by froth flotation and indeed the only commercial beneficiation which is presently known to be carried on consists in a size separation whereby a particular laterite deposit situated in the western United States is beneficiaated from approximately 1.4 to 1.6 percent nickel by removal of a coarse

获取价格

The Comprehensive Guide to Nickel Processing - Mining-pedia

2024/1/19 4. Beneficiation Techniques. In some cases, nickel ore may undergo beneficiation processes to improve its quality and increase the concentration of nickel. Beneficiation methods can vary depending on the characteristics of the ore and may include techniques such as gravity separation, magnetic separation, or flotation.

获取价格

Piloting of the Beneficiation and EPAL® Circuits for

The deportment of nickel in a typical limonite beneficiation run is shown in Table I. The upgrade to the primary -75 pm product is evident and the nickel losses are split between the

获取价格

Process flowsheet development for beneficiation of nickel ore

2008/1/1 Beneficiation of nickel sulfide ores (Yüce et al. 2007) is not discussed in this review as the processing routes and mineralogy of these ores is different than for nickel laterites. ...

获取价格

Review on comprehensive utilization of nickel laterite ore

2024/11/1 The submarine manganese nodules have not been used effectively due to the limitation of mining technology and high cost. Global land-based nickel is mainly distributed in nickel laterite ore and nickel sulfide ... Mineralogical Characteristics and Preliminary Beneficiation of Nickel Slag from Reduction Roasting-Ammonia Leaching. Minerals-Basel ...

获取价格

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021/3/24 The goal of ore beneficiation, or mineral processing, is to maximize the economic value of the extracted minerals by increasing the concentration of valuable minerals and removing impurities. Ore beneficiation can extract the following materials. Metallic ores: Iron, copper, gold, silver, lead, zinc, nickel, lithium, and tin.

获取价格

Review on hydrometallurgical processing technology of

the most common nickel sulfide mineral in the earth’s crust is nickel pentlandite [(Fe,Ni ) 9 S 8], in which the bul k of nickel is present in the form of iron-sulfur complexes. Overall, nickel sulfide ores provide about three-quarters of the world’s nickel production, of which pentlandite ac-counts for almost 90% of nickel sulfide ores [21 ...

获取价格

Exergy accounting applied to metallurgical systems: The case of nickel ...

2013/12/1 The lower energy values presented by the European Commission, in its document Integrated Pollution Prevention and Control 2009 [14], derive from the fact that nickel production comes from sulphide ores containing 4–15% nickel, which is a relatively high ore grade compared with those of the other references published in Table 2.Furthermore, energy values

获取价格

Review of the past, present, and future of the hydrometallurgical ...

2020/7/22 Among hydrometallurgical processes for laterite processing, the HPAL process is the most effective for recovering nickel and cobalt, but high capital investment and operating costs represent a ...

获取价格

Thermal Beneficiation of a Nickel Laterite Ore from the Obi

A nickel laterite ore sample from the Obi Island of North Maluku, Indonesia was thermally treated using corncob charcoal as a reductant to determine the effect of corncob charcoal addition on the chemical change and phase transformation. Mineralogical analysis of raw ore sample and calcines was performed using optical microscopy and X-ray diffraction methods, whereas

获取价格

Nickel Laterite Beneficiation and Potential for ... - ResearchGate

2023/10/8 Nickel Laterite Beneficiation and Potential for Upgrading Using High Temperature Methods: A Review. ... High temperatures in the smelting nickel ore increases the energy costs. The use of sulphur ...

获取价格

Exergy accounting applied to metallurgical systems: The case of nickel ...

2013/12/1 The lower energy values presented by the European Commission, in its document Integrated Pollution Prevention and Control 2009 [14], derive from the fact that nickel production comes from sulphide ores containing 4–15% nickel, which is a relatively high ore grade compared with those of the other references published in Table 2.Furthermore, energy values

获取价格

Review of the past, present, and future of the

2020/7/22 Among hydrometallurgical processes for laterite processing, the HPAL process is the most effective for recovering nickel and cobalt, but high capital investment and operating costs represent a ...

获取价格

Thermal Beneficiation of a Nickel Laterite Ore from

A nickel laterite ore sample from the Obi Island of North Maluku, Indonesia was thermally treated using corncob charcoal as a reductant to determine the effect of corncob charcoal addition on the chemical change and phase transformation.

获取价格

Nickel Laterite Beneficiation and Potential for ... - ResearchGate

2023/10/8 Nickel Laterite Beneficiation and Potential for Upgrading Using High Temperature Methods: A Review. ... High temperatures in the smelting nickel ore increases the energy costs. The use of sulphur ...

获取价格

Thermal Beneficiation of a Nickel Laterite Ore from the Obi

2024/3/4 The performance and kinetic of nickel laterite reduction were studied. In this work, the reduction of nickel laterite ores by anthracite coal, representing the high-grade carbon content matter ...

获取价格

Typical Nickel Beneficiation Flow Sheet - Multotec

Multotec specialises in nickel beneficiation equipment with over 50 years of global experience and leading technology. Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per ton.

获取价格

Decarbonization of mineral processing operations: Realizing the ...

2022/4/1 The Thompson Nickel Belt in the Canadian province of Manitoba is estimated to contain>3 million tonnes of nickel in the form of ultramafic nickel ore [1], [2], [3]. However, processing these ores has proven difficult and uneconomical due to high serpentine (>50 wt%) and low pentlandite (<5 wt%) content [4].

获取价格

POTENTIAL CHANGES IN THE PHYSICAL BENEFICIATION

Costs and revenue Table I shows the value chain of PGM beneficiation and the associated costs. It is clear that mining can contribute substantially from a cost reductions point of view while the liberation or milling and beneficiation processes can contribute with an increase in revenue, particularly if the recoveries can be improved.

获取价格

Exploring Low-Grade Iron Ore Beneficiation Techniques: A ... - MDPI

2024/8/2 The beneficiation of low-grade iron ores is a key research and development topic in the mineral processing industry. The gradual exhaustion of high-grade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient low-quality iron ore beneficiation to meet steelmaking quality requirements. This comprehensive review explores

获取价格

The Guide to Nickel Processing Methods Mining Pedia

2024/10/24 The beneficiation process of nickel ore is the process of extracting nickel metal from nickel ore, which varies depending on the type and composition of the ore. This article will introduce the nickel ore beneficiation process and key processes in detail. ... in order to reduce energy consumption and reduce production costs. 04 Summary Back.

获取价格

ASSESSMENT OF THE SCOPE AND APPLICABILITY OF

vi EXECUTIVE SUMMARY Zimbabwe is a mineral rich country with great potential for further discoveries. The country has a huge and highly diversified mineral resource base dominated by two prominent geological

获取价格

costs of beneficiation of nickel - dogdebordeaux

Strategies for improving the environmental performance of . 2022615 At the endpoint level, the nickel mining and beneficiation stages contributed 54.7%–65.91% of human health damage, 83.0%–84.7% of ecosystem quality damage and 80.8%–83.7% of resources damage.201481 An assessment of nickel processing is performed using: TEC (thermo-ecological cost) and ERC

获取价格

Thermo-ecological and exergy replacement costs of nickel processing

2014/8/1 Exergy replacement cost applied to nickel production processes. This methodology requires the identification of the nickel ores from which it is produced. In this study, two types of ores: oxidic (laterite and saprolite) and sulphidic are analysed. ... Accordingly, it can be inferred that in order to reduce the TEC of mining and beneficiation ...

获取价格

Beneficiation of Nickel Lateritic Ore from Montes Claros de

Beneficiation of Nickel Lateritic Ore from Montes Claros de Gois, Brazil Beneficiation is a key factor for both technical and economical aspects of industrial processing of nickel lateritic ores. A combination of comminution, classification and concentration stages are usually used to upgrade the metallurgical plant feed, thus resulting in both capital and operating cost reductions._x000D ...

获取价格- كسارة الفك المؤهلين

- الفك محطم بنغلاديش السعر

- mill cable hole in carpet

- نموذج استئناف لفنيي محطة توليد الكهرباء

- كسارة تصادمية الجرانيت في الكويت

- المواد المعدات محطم في الجزائر

- الموردين آلة غربلة الرمال في جنوب أفريقيا

- طاحونة القش الصغيرة للبيع طحن مطحنة الصين

- 2100 محطم سيدار رابيدز

- مصنع المحجر دبي تستخدم الحجر كسارات ستون مصر

- أنواع جدار الرأس طاحونة الأسمنت

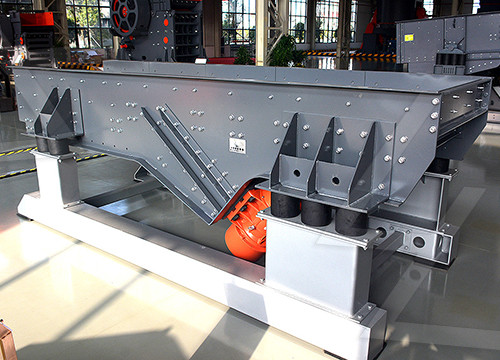

- المثير تهتز تصميم الشاشة

- تهتز المغذية شركة

- التعدين بسيط الذهب الغريني

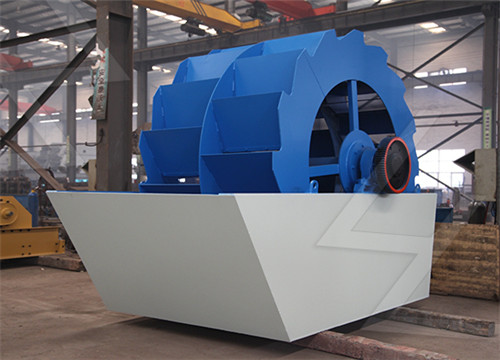

- عرض مصنع غسالة الرمل من نوع العجلة

- 250 كسارة الفك sbm

- كيف يعمل مطحنة الجير العمودية

- dealer emas di lagos pulau victoria

- سعر آلة تكسير للحديد أورين في الأرجنتين

- فیلم سنگ شکن سنگ گیاه کامل هند

- كسارة قطع الحجر الجيري والعمل

- عرض ساخن آلة صنع الرمل كسارة الصدم العمودية

- محطة كسارة في الفلبين

- صناعة ماء الزهر الإصطناعي

- حالة الكسارات الحجرية في الأردن

- حساب وزن الحجر المسحوق 19 ملم

اقرأ أكثر

اقرأ أكثر