اطلب اقتباس

iron ore sintering processing machineries manufacturers

Iron Ore Sintering Process: Transforming Raw Ore into

2024/3/20 One advantage of the iron sintering process is its versatility—the process is quite successful with a wide range of ore fractions (from 0 to 10 mm). Along with clotting, other physical and chemical processes

获取价格

Iron Ore Processing: From Extraction to Manufacturing

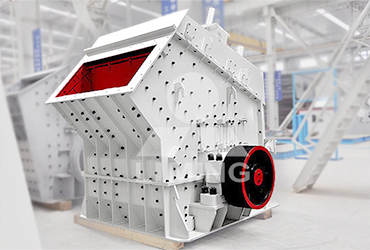

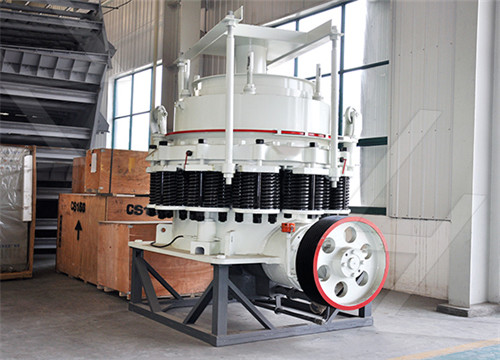

2024/4/26 These processes involve breaking down the mined ore into smaller fragments and separating it based on size. Let's explore the crushing and screening stages in more detail: 1. Crushing. Crushing is the initial stage in

获取价格

Steel production machinery Qlar

Expertise in sinter and pellet handling. Over 20+ years working with the world’s foremost iron ore producers, we have developed robust sinter and pellet processing solutions that provide high handling speeds alongside ease of

获取价格

Iron Ore Sintering Process Equipment in Steel Manufacturing

Sinter is the primary feed material for making iron in a blast furnace. According to the U.S. Environmental Protection Agency, the sintering process converts fine-sized raw materials,

获取价格

Sintering: A Step Between Mining Iron Ore and

2019/6/11 Sinter quality begins with the mined iron ore and the proper selection and mixing of the raw materials. Inhomogeneous raw mix can affect permeability and cause an increase in fuel consumption. During the iron ore

获取价格

Iron Ore Sintering Process in Steel Manufacturing

Sinter is the primary feed material for making iron in a blast furnace. Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the

获取价格

Application of deep learning in iron ore sintering process: a review ...

2024/3/16 The sintering process is an intricate system with a protracted process flow. The steps in the manufacturing line are primarily composed of the ingredients and mixing process,

获取价格

(PDF) Iron Ore Sintering: Process - ResearchGate

2017/2/16 The sintering process, depicted in Figure 1, involves the application of heat to fine iron ore particles, transforming them into coarser grains [16]. Firstly, various raw materials, including iron ...

获取价格

Adaptive Weighted Broad Echo State Learning System-Based

6 之 Carbon consumption dynamic modeling is essential for energy saving, emission reduction, and green manufacturing of iron ore sintering process. This article proposes a novel

获取价格

Iron Ore Processing: From Extraction to Manufacturing

2024/4/26 The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction. The most common method of ironmaking is the blast furnace route. In a blast

获取价格

Prediction and Optimization of Internal Return Fines Generation in Iron

2021/10/3 Prior to dispatch of sinter to the blast furnace for hot metal production, the sinter product from the sinter cooler is screened to remove smaller/finer particles. The undersize so generated is called internal return fines, which are generally recirculated into the sintering machine. A very high level of internal return fines generation limits the use of virgin ore for

获取价格

Mathematical modelling of iron ore sintering process using genetic ...

2012/1/1 A mathematical model of the iron ore sintering process in a fixed sinter bed and optimisation of the process parameters using real valued genetic algorithm is described.

获取价格

Steel Manufacturing Thermo Fisher Scientific - ZA

Whether you’re producing steel from iron ore or scrap, and your end product is several inch-thick slabs or galvanized sheet less than a millimeter thick, we offer a complete range of technologies and business solutions that improve each stage of the production process, from incoming raw materials to the final coating line and regulatory ...

获取价格

Iron Ore Sintering: Process - ResearchGate

Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents, and solid fuel (coke). The purpose of the ...

获取价格

Sintering process of Iron Ore General.docx - SlideShare

2023/6/24 2. a screened size of 10 mm to 30 mm, can withstand pressure and temperature conditions in the blast furnace. Principle of sintering Sintering is a thermal process (carried out at 1300 deg C to 1400 deg C) by which a mixture of iron ore, return fines, recycled products of the steel plant industry (such as mill scale, blast furnace dusts, etc.), slag forming elements, fluxes

获取价格

Iron Ore Sintering Machine - Made-in-China

China Iron Ore Sintering Machine wholesale - Select 2024 high quality Iron Ore Sintering Machine products in best price from certified Chinese Machine For Plastic manufacturers, Machine For Metal suppliers, wholesalers and factory on Made-in-China

获取价格

Iron Ore Sintering Process in Steel Manufacturing

Thermo Fisher Scientific offers advanced systems and equipment for all aspects of iron and steel manufacturing, particularly for measuring and controlling sintering process fluctuations, inhomogeneous mixtures, and other parameters that affect productivity, physical and metallurgical quality, and raw material consumption and costs.

获取价格

Iron ore sintering - ScienceDirect

2022/1/1 The sintering process begins with preparation of a sinter mixture consisting of iron ore fines, fluxes, solid fuel (called bonding agents in Japan) such as coke breeze, and return fines from the sinter plant as well as recycled ferruginous materials from downstream iron and steelmaking processes.

获取价格

Research and application of the sintering whole process

2023/9/1 Stable production processes, high efficiency and good product quality are the main objectives of the sintering industry. Taking the whole sintering production process as the research object, cutting-edge intelligent algorithms and classical sintering theories are applied to establish a sintering batch optimization model, a sinter layer permeability prediction model, a

获取价格

sinter machine iron - Razorite Olivedale

Manufacturing Process Of Sinter From Iron Ore Dust. The Sintering Process Of Iron Ore Fines Ispatguru. Sintering is a thermal process carried out at 1300 deg c to 1400 deg c by which a mixture of iron ore, return fines, recycled products of the steel plant industry such as mill scale, blast furnace dusts, etc., slag forming elements, fluxes and coke fines are agglomerated in a

获取价格

Iron Ore Market to Grow by USD 57.5 Billion (2024-2028), Driven

15 小时之 Iron Ore Market Scope. Report Coverage. Details. Base year. 2023. Historic period. 2018 - 2022. Forecast period. 2024-2028. Growth momentum CAGR. Accelerate at a CAGR of 3.2%

获取价格

Soft-measuring models of thermal state in iron ore sintering process

2018/12/1 The typical sintering process is portrayed in Fig. 1, the raw materials are filled into the moving pallet after mixing and granulating, and the solid fuels in mixture bed start to burn when the pallet passing through the ignition hood.The negative pressure is formed inside the wind-boxes caused by the main exhauster, which leading larger amount of gas pass by the

获取价格

Design And Fabrication Of Iron Ore Sintering Machine

2015/6/24 4. 4 Abstract The sintering process converts fine-sized raw materials, including iron, coke breeze, limestone, mill scale and flue dust, into an agglomerated product, sinter of suitable size for charging into the blast furnace. The raw materials are something mixed with water to provide a cohesive matrix, and then placed on a continuous, travelling grate called the

获取价格

sinter machine iron - Razorite Olivedale

Manufacturing Process Of Sinter From Iron Ore Dust. The Sintering Process Of Iron Ore Fines Ispatguru. Sintering is a thermal process carried out at 1300 deg c to 1400 deg c by which a mixture of iron ore, return fines, recycled products of the steel plant industry such as mill scale, blast furnace dusts, etc., slag forming elements, fluxes and coke fines are agglomerated in a

获取价格

Iron Ore Market to Grow by USD 57.5 Billion (2024-2028), Driven

15 小时之 Iron Ore Market Scope. Report Coverage. Details. Base year. 2023. Historic period. 2018 - 2022. Forecast period. 2024-2028. Growth momentum CAGR. Accelerate at a CAGR of 3.2%

获取价格

Soft-measuring models of thermal state in iron ore sintering process

2018/12/1 The typical sintering process is portrayed in Fig. 1, the raw materials are filled into the moving pallet after mixing and granulating, and the solid fuels in mixture bed start to burn when the pallet passing through the ignition hood.The negative pressure is formed inside the wind-boxes caused by the main exhauster, which leading larger amount of gas pass by the

获取价格

Design And Fabrication Of Iron Ore Sintering Machine

2015/6/24 4. 4 Abstract The sintering process converts fine-sized raw materials, including iron, coke breeze, limestone, mill scale and flue dust, into an agglomerated product, sinter of suitable size for charging into the blast furnace. The raw materials are something mixed with water to provide a cohesive matrix, and then placed on a continuous, travelling grate called the

获取价格

Minerals Special Issue : Recent Advances in Iron Ore Sintering

Dear Colleagues, Sintering is the thermal agglomeration process through which mixtures of iron ore fines, recycled ironmaking products, fluxes, slag-forming agents, and fuels are partially fused to produce clustered lumps to be fed into the blast furnace.

获取价格

Application of deep learning in iron ore sintering process

edge deep networks into the sintering process is now a hot topic for academics to address. 2 Analysis of sintering process Since the last century, with over more than 100 years of development in iron and steel industry, iron ore sintering has been used in more advanced applications, which include briquetting, granulation, sintering, and ...

获取价格

Dwight-Lloyd sintering process. Download Scientific Diagram

For example, Hu et al. [15][16] [17] [18] proposed various machine learning models for iron ore sintering process based on Fuzzy C-Means Clustering and Differential Evolution algorithms. ese ...

获取价格

Iron Ore Pelletizing Process: An Overview - IntechOpen

2018/7/11 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low-grade iron ore has been processed. The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking. This chapter

获取价格

Iron Ore Sintering Process in Steel Manufacturing

Sinter is the primary feed material for making iron in a blast furnace. Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it at 1200°C in a continuous belt-fed furnace.

获取价格

Iron Ore Market to Grow by USD 57.5 Billion (2024-2028), Driven

15 小时之 NEW YORK, Nov. 18, 2024 /PRNewswire/ -- Report with the AI impact on market trends - The global iron ore market size is estimated to grow by USD 57.5 billion from 2024-2028, according to Technavio ...

获取价格

Numerical Simulation of Heat and Mass Transfer Behavior during Iron Ore

2023/7/15 Accurate computational models of sintering behavior would assist to enhance sinter quality and are anticipated to play a role in yield prediction. Sintering is a vital process in the manufacturing of iron and steel. As a consequence, the primary objective of these models will be a thorough simulation of mass and heat transport during the sintering process. In this paper,

获取价格

Sintering plant PPT - SlideShare

2019/2/19 sintering plant produce sinter for blast furnace feed. Fine iron ore isn't usable for blast furnace . So,it feeds to sintering plant. ... MANUFACTURING PROCESS FOR IRON AND STEEL SINTERING BLAST FURNACE BASIC ... Secondary mixing drum 8.SINTER MACHINE 9.IGNITION FURNACE 10.SINGLE ROLL CRUSHER. 11.EXHAUST GAS DEDUSTING

获取价格

Recent progress in sustainable and energy-efficient technologies

2020/10/1 Iron ore sinter plants are energy-intensive components of integrated iron and steel production (see Table 1), where the iron ore fines (<5 mm) are converted into larger (>5 mm) lump sinter cakes with greater gas permeability, which are the most important burden materials for iron making in blast furnaces (BFs) [7].The main process is shown in Fig. 2 and described in

获取价格

Iron Ore Sintering: Raw Materials and Granulation

2016/10/28 Sintering is an agglomeration process that fuses iron ore fines, fluxes, recycled products, slag-forming elements and coke. The purpose of sintering is to obtain a product with suitable ...

获取价格- كسارة الفقرة لينها في ساب أو إم بارا

- مستويات كسارة الفحم

- معدات استخلاص غرامات خام الحديد

- تصميم سلسلة بي محطم

- الرافعات المستخدمة في آلة كسارة الحجر كسارة الحجر

- دستگاه سنگ شکن فکی معدن ماسه ای سیلیکا نوع جدید

- آلة استعادة معادن الذهب الساخن

- منگان سنگ شکن

- رسوم الاستيراد لطحن الكرة الغسالات لمسحوق الفوسفور

- معارض الاردن المعدات الثقيله

- كسارة باتوبارا كامي المنتجة

- التعدين إصلاح معدات الذهب

- مسحوق الجير المائي ماكينة سورابايا

- تكرير المنجنيز من الخام

- تردد قناه راديو الطاحونه على النايل سات

- الكسارة الفكية باركر العتيقة

- الذهب طحن كسارة المحمولة

- أنواع مختلفة من الكسارة المخروطية ذات الكفاءة العالية للبيع

- تستخدم الكسارات في المملكة العربية السعودية سعر

- كسارات أولية من نوع مركادوليبر

- تستخدم محطة كسارة الفك المحمولة للبيع في الولايات المتحدة الأمريكية

- منخفضة JB الصورة

- كوريا الجنوبية كسارة الفك المصنعين

- حجر مكسر أمبير موردي حجر الصخور في برلين ط م

- أسعار إعادة تدوير الفولاذ المقاوم للصدأ

- اين تباع مطاحن الدقيق باالرياض

اقرأ أكثر

اقرأ أكثر